Better Buffers

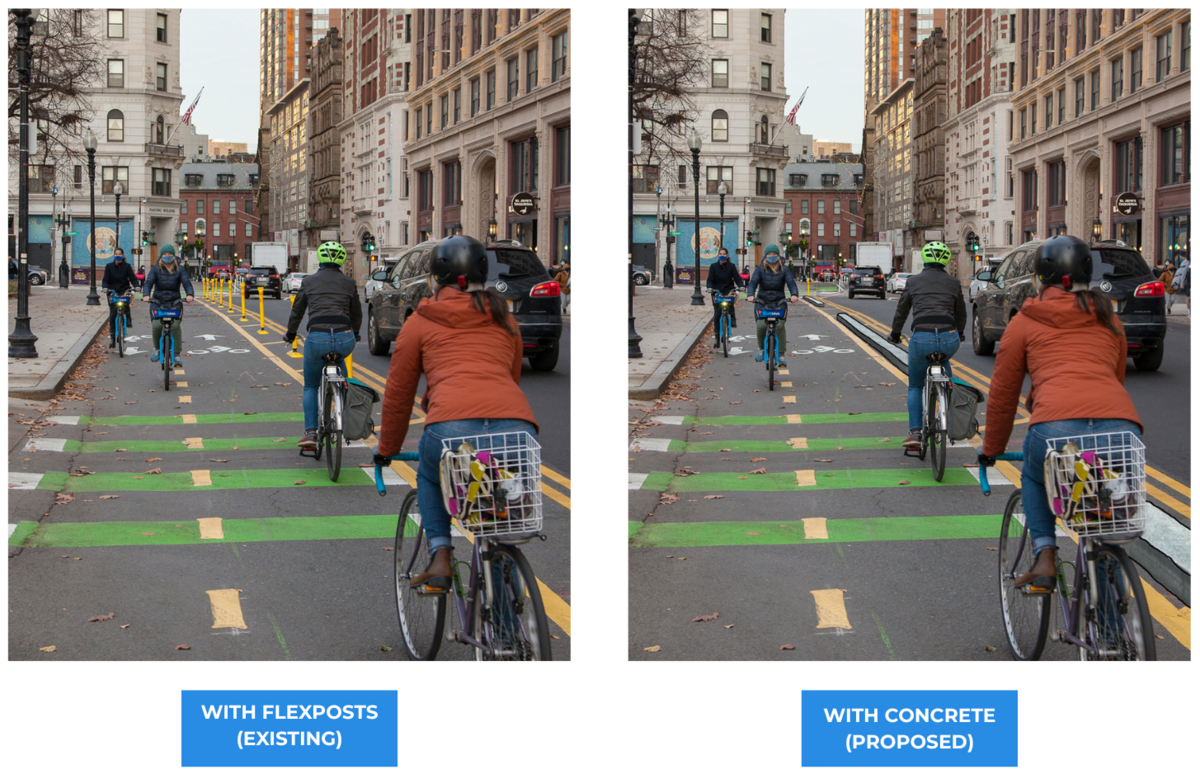

We’re replacing flexposts installed through past safety projects with more durable materials.

We’re switching out materials to enhance safety for all travelers.

WHY WE’RE UPGRADING MATERIALS

- Flexposts have improved safety on our streets: they help pedestrians safely cross the street and separate people riding bikes from travel lanes.

- And yet, flexposts are costly to maintain and contribute to litter when damaged.

- We understand that many residents are ready to see the safety interventions that protect their families and neighbors made permanent.

STRONGER MATERIALS

- We’ve been developing an alternative to flexposts based on solutions that work in other North American cities such as Seattle, Minneapolis, San Diego, and Edmonton, Canada.

- Cast-in-place concrete can be designed and installed relatively quickly and with comparable costs to flexposts. Unlike fully-constructed curbing, cast-in-place concrete is formed on top of the roadway, which greatly reduces the cost and complexity for construction when compared to full reconstruction projects. Concrete will last longer and provide more substantial protection to vulnerable road users than flexposts.

- Like flexposts, concrete can be used in a wide variety of safety design features including pedestrian crossing islands, clear corners, and separated bike lanes.

- When replacing flexposts with concrete, our design teams ensure that:

- All travelers can safely navigate the street, including ensuring vehicles can make turns at intersections. In some cases, a limited number of flexposts may remain in place to allow for visibility or in places where concrete cannot be installed.

- Accessible paths for people with disabilities are not obstructed

- All utility companies will be able to access their underground infrastructure

Better Buffers Locations

We’re focused on replacing flexposts with concrete at locations that:

-

Will provide a significant safety benefit over flexposts

-

Have experienced the most wear-and-tear and maintenance costs since flexposts were originally installed

-

Have proven designs that have been installed with flexposts or other interim materials for several years

CONSTRUCTION PROCESS

In most cases, active construction should take just a few days (weather dependent) with minimal disturbance to the surrounding streets. Contractors will:

- Remove existing flexposts

- Build wooden forms for the concrete

- Pour the concrete and insert signposts

- Allow the concrete to harden

- Remove the wooden forms

- Install any final accessibility elements

BEHIND THE SCENES

-

Using concrete in the roadway sounds simple and commonplace, but the City hasn’t applied concrete built in this particular way for these uses before. Since we are introducing a new (to Boston) treatment to the roadway, we wanted to experiment with it first.

-

This past spring, we tested out variations of our concrete designs at a Public Works yard. We tested various concrete mixes, shapes, dimensions, and potential applications. We considered a range of criteria including accessibility, constructability, durability, and visibility.

- Here are some photos from our test site (we’ve adjusted our designs since these photos were taken):

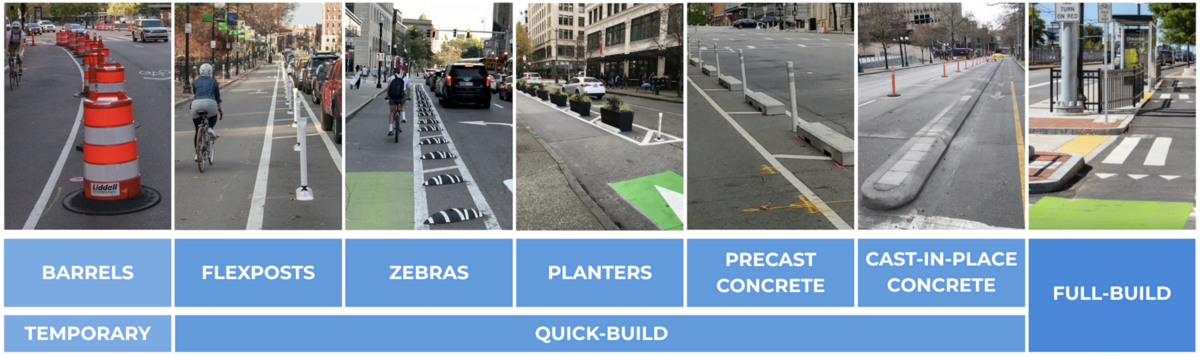

Other Buffer Types

We choose buffer materials based on what works best for each street. For separated bike lanes, space is usually the main factor: we need to leave room for street sweepers and snow plows. We also take into account how the area is used, whether it’s next to a parking lane or travel lane, if it’s on a bridge or solid ground, and the project budget. Some buffer types - specifically planters - require a maintenance partner to be identified before they may be considered.